Monitoring of the foundation structures of offshore structures

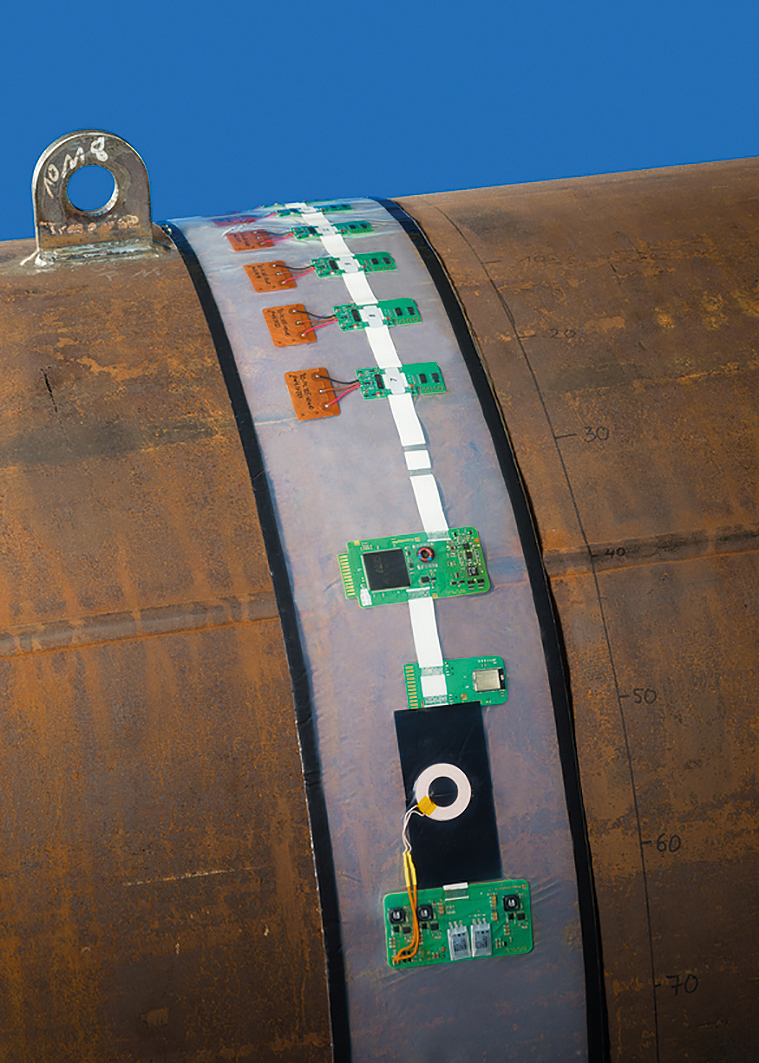

In the "SOT Digital Twin" project, the focus is on monitoring and evaluating offshore structures using a measuring belt (CoMoBelt®) developed at Fraunhofer IKTS. The CoMoBelt® – a belt equipped with sensors – can permanently monitor underwater structures and detect damage in the structure by means of so-called guided waves. The data can be read out underwater without having to perform risky diving operations. ROVs (Remote Operating Vehicles) also developed at the SOT are used for this purpose, which then transmit the data by radio and feed it into a digital twin. With this data-fed 3D model, the difficult-to-access underwater structure as well as defects or material fatigue can be realistically displayed on land.

Digital twin for inspection planning and estimation of residual life span

In order for the digital twin to adequately process the measurement data, it must be classified and analyzed. The AI solution developed by the project partners "University of British Columbia" and "National Research Council of Canada NRC" takes on this task and also displays the data using augmented reality or mixed reality. This enables the maintenance engineer to view a 3D image of the monitored structure overlaid with the measured data. If this is done via a smartphone or data glasses, maintenance can be planned on site, as weak points are directly identifiable and can be inspected immediately. In addition, the remaining service life can be estimated with the help of the digital twin and simulations.

Extending the life cycle of offshore structures

In the course of the project, the collected measurement data and various physical models will also be used to make statements about the remaining service life in order to coordinate maintenance measures efficiently. Such projects help not only to make maintenance more economical, but also to extend the life cycle of these plants. This means that an intact plant can be operated beyond its planned lifetime, as permanent monitoring and damage prediction enable safe operation. Dismantling or new construction can thus be postponed, if not avoided. This saves time, costs and resources.

You see other interesting applications? Contact us!